ANA SAYFA

ANA SAYFA

TÜM MAKİNELER

TÜM MAKİNELER

Hava kabarcığı filmi makine serisi

Hava kabarcığı filmi makine serisi

7 katmanlı balonlu film makinesi(3 vidalı ekstruder)

7 katmanlı balonlu film makinesi(3 vidalı ekstruder)

7 katmanlı balonlu film makinesi

(3 vidalı ekstruder)

Ana parçalar

Ekstruder, Kontrol Paneli, Şekillendirme Bölümü, Çekiş Bölümü, Sarma Bölümü.

Mobil / Whatsapp:

Bize e-posta gönderin

Performans ve kullanım

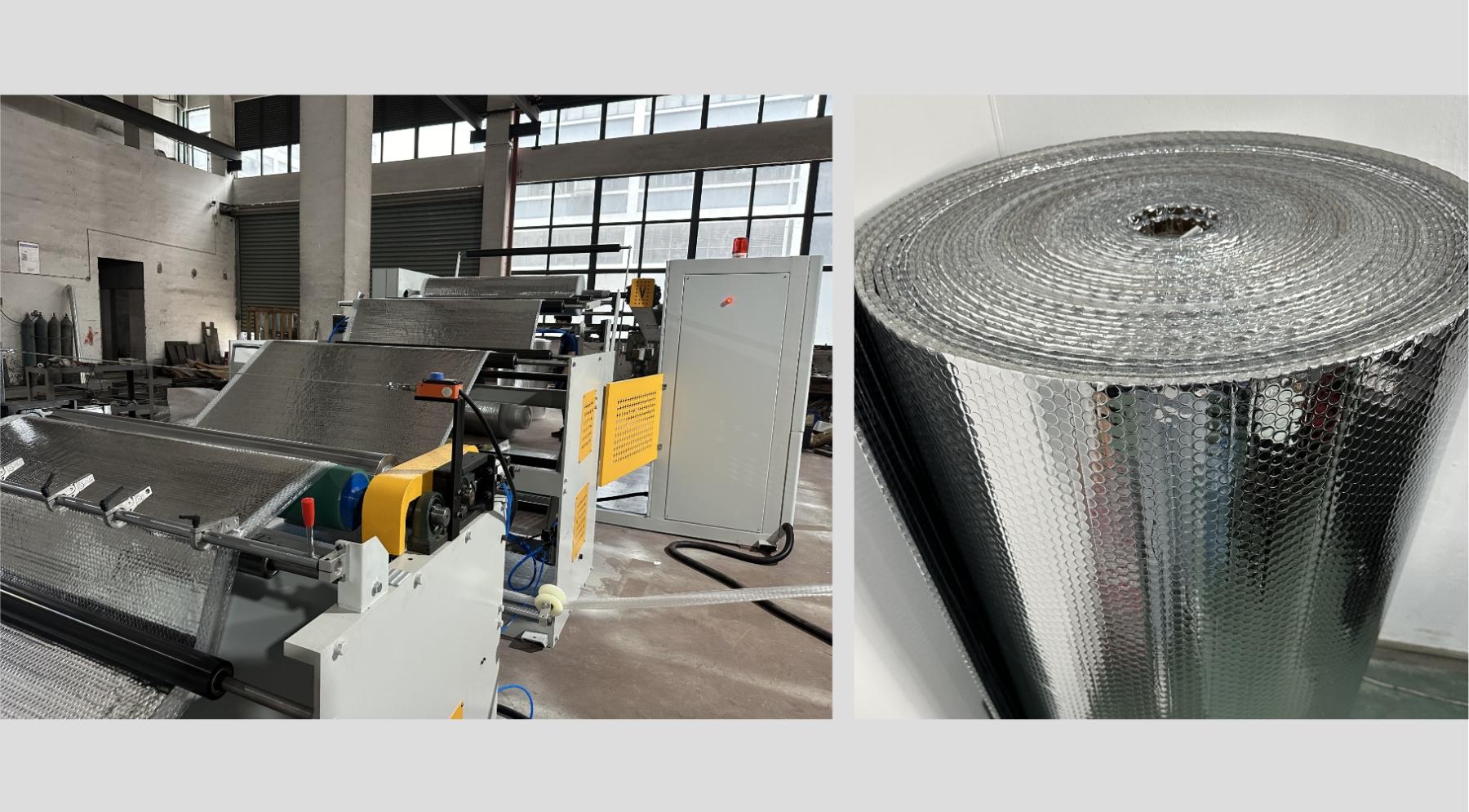

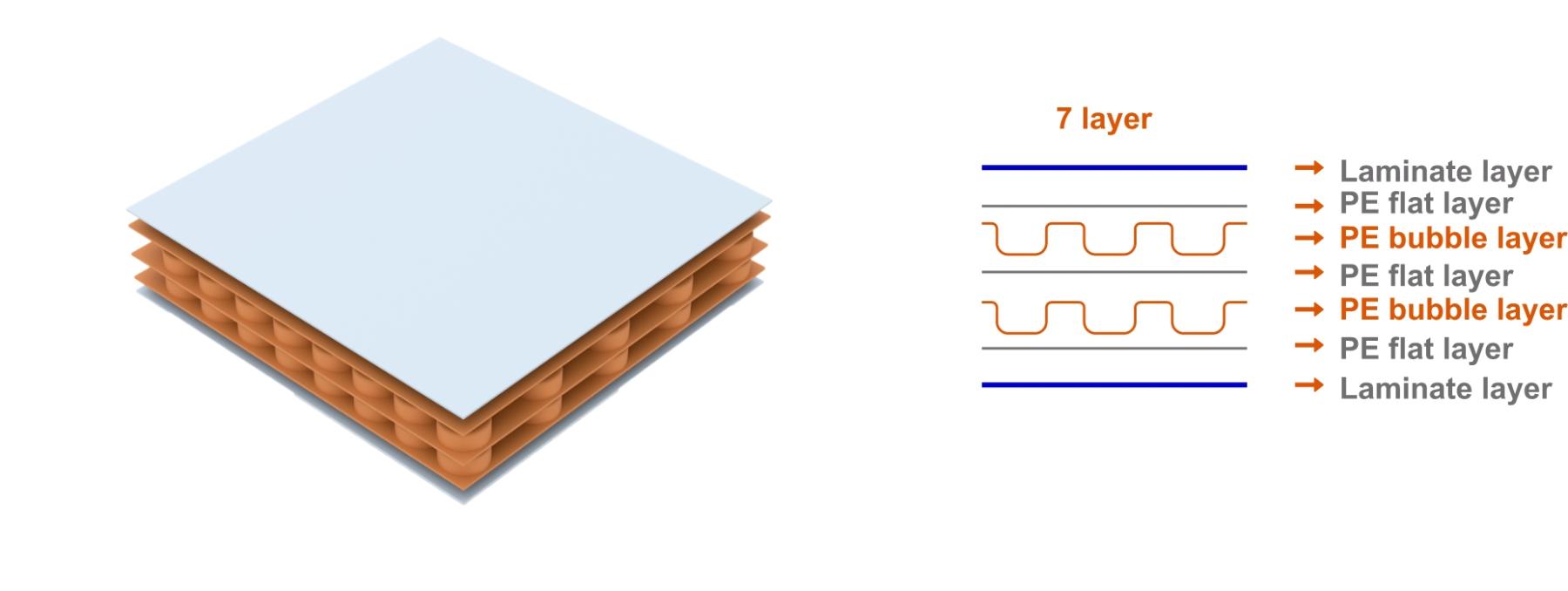

7 katmanlı hava kabarcıklı film makinesi esas olarak 1 numaralı ana ekstruder (tek vida), ikincil ekstruder (tek vida), 2 numaralı ana ekstruder (tek vida), şekillendirme ünitesi, kompozit film laminasyon ünitesi (2 set), sarma ünitesi ve elektronik kontrol sisteminden oluşur. 3 ekstruder 5 katmanlı kabarcık filmler üretir, bu arada alüminyum folyo, kraft kağıdı, EPE köpük gibi kompozit malzemeler de eklenebilir.

7 katmanlı hava kabarcıklı yalıtım folyosu, ısı yalıtım özelliği sayesinde inşaat sektörü, bagaj sektörü, soğutma sektörü ve paketleme sektörü dahil birçok endüstride yaygın olarak kullanılmaktadır. Yol, havaalanı pistleri, menfezler ve köprüler için darbe dayanımlı ve genleşme önleyici malzeme olarak yapı malzemesi olarak kullanılabilir. Ayrıca binalar ile çevre arasındaki ısı alışverişinin %80'ine kadarını engellemek için çatılara, duvarlara ve zeminlere monte edilebilir. Bu şekilde sıcaklığı korur, böylece hızla düşmez. Ek bir koruma katmanı, ısının kaçmasını daha iyi önler, böylece daha iyi bir ısı yalıtım etkisi elde edilir.

Her katman ayrı ayrı kontrol edilir, farklı kalınlıkta,

malzeme formülü ve renkte olabilir.

| Model | WD-1000mm | WD-1250mm | WD-1500mm | WD-1600mm | WD-1800mm | WD-2000mm | WD-2500mm | WD-3000mm |

| Ürün genişliği(mm) | 1000 | 1250 | 1500 | 1600 | 1800 | 2000 | 2500 | 3000 |

| Vida Çapı(mm) | 65/55/65 | 65/55/65 | 75/65/75 | 75/65/75 | 80/65/80 | 85/75/85 | 95/80/95 | 110/85/110 |

| Vida L:O Oranı | 32:1 | 32:1 | 32:1 | 32:1 | 32:1 | 32:1 | 32:1 | 32:1 |

| Ana motor gücü(kw) | 18.5/15/18.5 | 18.5/15/18.5 | 22/18.5/22 | 22/18.5/22 | 30/18.5/30 | 37/22/37 | 45/30/45 | 55/37/55 |

| Kapasite(kg/sa) | 90-150 | 100-160 | 130-190 | 145-200 | 160-240 | 180-280 | 200-310 | 230-350 |

| Hat hızı(m/sa) | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 500-1300 | 500-1300 |

| Isıtma Gücü(kw) | 85 | 85 | 102 | 102 | 136 | 150 | 155 | 170 |

| Çalışma Gücü(kw) | 56 | 56 | 62 | 62 | 95 | 120 | 135 | 145 |

| Hammadde | LDPE/LLDPE/ 100%Geri Dönüştürülmüş Malzeme |

LDPE/LLDPE/ 100%Geri Dönüştürülmüş Malzeme |

LDPE/LLDPE/ 100%Geri Dönüştürülmüş Malzeme |

LDPE/LLDPE/ 100%Geri Dönüştürülmüş Malzeme |

LDPE/LLDPE/ 100%Geri Dönüştürülmüş Malzeme |

LDPE/LLDPE/ 100%Geri Dönüştürülmüş Malzeme |

LDPE/LLDPE/ 100%Geri Dönüştürülmüş Malzeme |

LDPE/LLDPE/ 100%Geri Dönüştürülmüş Malzeme |

| Makine Ağırlığı(kg) | 9800 | 10800 | 13200 | 13800 | 14600 | 16300 | 18500 | 19800 |